A na-emepụta PVC site na vinyl chloride site na polymer radical free.Site na polymerization nkwusioru, emulsion polymerization na nnukwu polymerization, polymerization nkwusioru bụ ụzọ bụ isi, na-aza ihe dịka 80% nke mmepụta PVC zuru ezu.N'ime ụlọ ọrụ ahụ, usoro mmepụta PVC na-adaberekarị na usoro nke inweta vinyl chloride monomer ịmata ọdịiche, enwere ike kewaa ya na usoro calcium carbide, usoro ethylene na mbubata (EDC, VCM) usoro monomer (nke a na-akpọ usoro ethylene na usoro monomer ebubata) .Dị ka usoro mmepụta ihe dị iche iche si dị, a na-ekewa PVC ntụ ntụ: resin PVC zuru ụwa ọnụ, resin PVC nwere ogo dị elu nke polymerization, crosslinking PVC resin.Emebere resin PVC zuru ụwa ọnụ site na polymerization nke vinyl chloride monomer n'okpuru ọrụ nke onye mbido;PVC resin nwere ogo dị elu nke polymerization na-ezo aka na resin nke etolite site na ịgbakwunye ihe na-abawanye ụbara mmadụ na usoro polymerization nke vinyl chloride monomer;resin PVC crosslinked bụ resin nke a na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ onye na-ejikọta crosslink nwere diene na polyene na usoro polymerization nke vinyl chloride monomer.

Nkwusioru polyvinyl chloride resin ụdị ugbu a:

Sg-1: K 77-75 nkezi ogo nke polymerization

Sg-2: K 74-73 nkezi ogo nke polymerization

Sg-3: K uru 72-71 Nkezi polymerization ogo 1350-1250

Sg-4: K uru 70-69 nkezi ogo nke polymerization 1250-1150

Sg-5: K uru 68-66 Nkezi ogo nke polymerization 1100-1000

Sg-6: K uru 65-63 Nkezi ogo nke polymerization 950-850

Sg-7: K uru 62-60 nkezi ogo nke polymerization 850-750

Sg-8: K uru 59-55 nkezi ogo nke polymerization 750-650

Ngwa ngwa:

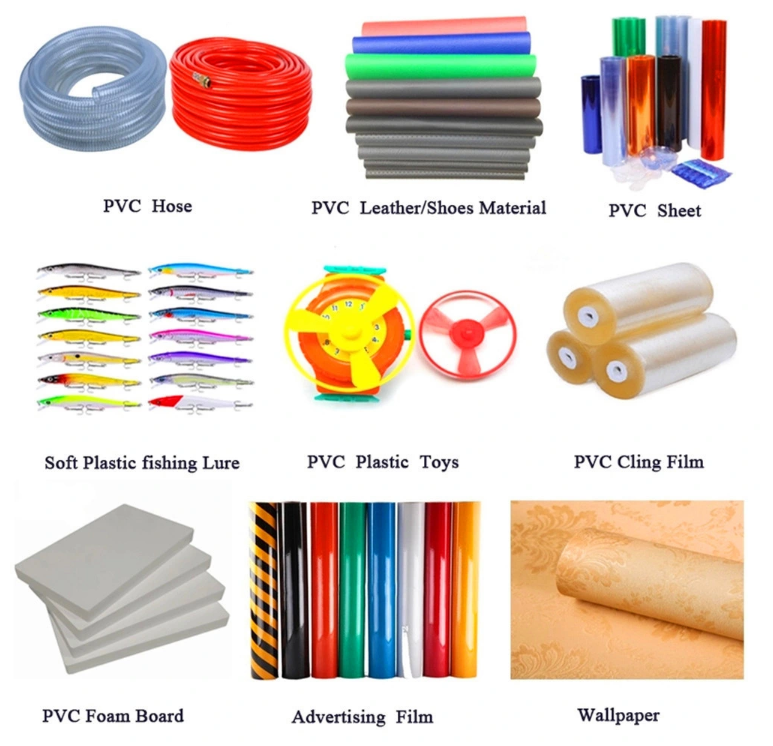

Enwere ike ịhazi resin PVC n'ime ngwaahịa plastik dị iche iche, dịka ojiji ya nwere ike kewaa ụzọ abụọ nke ngwaahịa dị nro na nke siri ike, nke a na-ejikarị na-emepụta mpempe akwụkwọ transperent, ọkpọkọ ọkpọkọ, kaadị ọla edo, ngwa mmịnye ọbara, dị nro na siri ike. ọkpọkọ, efere, ọnụ ụzọ na Windows, profaịlụ, ihe nkiri, ihe mkpuchi ọkụ eletrik, n'ọbọ USB, ihe mmịnye ọbara, wdg.

1.PVC izugbe dị nro na ngwaahịa siri ike - iji extruder nwere ike ịkụnye n'ime ọkpọkọ dị nro na nke siri ike, eriri, wires, wdg;Iji igwe na-akpụzi injection na ụdị dị iche iche, enwere ike ịme ya ka ọ bụrụ akpụkpọ ụkwụ rọba, ọbụ ụkwụ, slippers, ihe egwuregwu ụmụaka, ihe ndị dị mkpa kwa ụbọchị na ụgbọ ala na ngwa eletriki.

2 PVC siri ike ọkpọkọ na profaịlụ - n'ihe metụtara plastik ndị ọzọ, PVC ịka nká na-eguzogide dị mma, ike dị elu na ike siri ike, ọnụ ala dị ala, kwesịrị ekwesị maka ọkpọkọ mmiri na ihe ndị ọzọ na-ewu ụlọ, na profaịlụ profaịlụ.

3 PVC ihe nkiri - PVC na ihe mgbakwunye agwakọta, plasticizing, ojiji nke atọ ma ọ bụ anọ mpịakọta usoro n'ime kpọmkwem ọkpụrụkpụ nke transperent ma ọ bụ acha film, na nke a usoro nhazi film, ghọọ calending film.Enwere ike ịkpụ, akpa nkwakọ ngwaahịa okpomọkụ, uwe mmiri ozuzo, akwa tebụl, ákwà mgbochi, ihe egwuregwu na-eku ume na ihe ndị ọzọ.Enwere ike iji ihe nkiri transperent sara mbara maka griin haus, griin haus plastik na ihe nkiri plastik.Mgbe bidirectional na-agbatị ihe nkiri ahụ, ihe onwunwe nke okpomọkụ shrinkage, nwere ike iji mee ihe maka ịkwakọ ngwaahịa.

4 PVC mkpuchi ngwaahịa - na mkpụrụ nke akpụkpọ anụ artificial bụ PVC mgbagwoju anya na ákwà ma ọ bụ akwụkwọ, na mgbe ahụ na 100 degrees Celsius n'elu plasticized.nwekwara ike ịbụ PVC na inyeaka calendering film, wee pịa ọnụ na mkpụrụ.The wuru akpụkpọ anụ na-enweghị mkpụrụ bụ kpọmkwem calended site calendering igwe n'ime a ụfọdụ ọkpụrụkpụ nke rọrọ mpempe akwụkwọ, wee pịa na ụkpụrụ.Enwere ike iji akpụkpọ anụ arụrụ arụ rụọ akpa akpa, akpa, mkpuchi akwụkwọ, sofas na ọdụ ụgbọ ala, na akpụkpọ anụ ala, nke a na-eji dị ka ihe eji eme ụlọ.

5.PVC ngwaahịa ụfụfụ - ngwakọta PVC dị nro, gbakwunye ezigbo onye na-emepụta ihe na-emepụta ihe na-eme ka ọ bụrụ ihe na-eme ka ọ bụrụ ihe mpempe akwụkwọ, ọkpụkpụ ụfụfụ maka ụfụfụ ụfụfụ, akpụkpọ ụkwụ ụfụfụ, akpụkpọ ụkwụ, insoles, na ihe nkwakọba ihe na-ekpuchi ọkụ.Nwekwara ike iji extruder FOUNDATION n'ime obere ụfụfụ siri ike PVC mpempe akwụkwọ na profaịlụ, nwere ike dochie osisi ikpe, bụ ọhụrụ ụdị ihe ụlọ.

6 PVC transperent mpempe akwụkwọ - PVC tinye mmetụta modifier na stabilizer, mgbe agwakọta, plasticizing, calending na-aghọ transperent mpempe akwụkwọ.Ojiji nke na-ekpo ọkụ akpụ nwere ike ime ka ọ bụrụ mkpa-mgbidi transperent containers ma ọ bụ jiri maka agụụ blister nkwakọ, bụ ihe magburu onwe nkwakọ ngwaahịa na ihe ịchọ mma.

7 PVC siri ike efere na efere - PVC stabilizer, mmanu na ndochi, mgbe agwakọta, na extruder nwere ike extruded dị iche iche caliber nke siri ike ọkpọkọ, pụrụ iche ụdị ọkpọkọ, bell, eji dị ka a downpipe, mmanya anwụrụ, waya aka uwe ma ọ bụ steepụ handrail.Mkpịsị ọkụ na-ekpo ọkụ nke mpempe akwụkwọ calended nwere ike ime mpempe akwụkwọ siri ike nke ọkpụrụkpụ dị iche iche.Enwere ike ịkpụ efere ahụ n'ụdị a chọrọ, wee jiri PVC electrodes na ikuku ọkụ na-ekpo ọkụ na-ekpo ọkụ n'ime tankị nchekwa dị iche iche nke corrosion na-eguzogide ọgwụ, ikuku ikuku na arịa.

8.PVC ọzọ - ọnụ ụzọ na Windows na-mere nke siri ike pụrụ iche-ekara ihe.Na mba ụfọdụ enweela ọnụ ụzọ osisi na Windows aluminum Windows na ọnụ ụzọ ndị ọzọ na ahịa Windows;Ihe nṅomi osisi, ọgbọ ígwè ihe ụlọ (n'ebe ugwu, oké osimiri);Akpa oghere.

Oge nzipu: Ọgọst-08-2022