Imepụta PVC

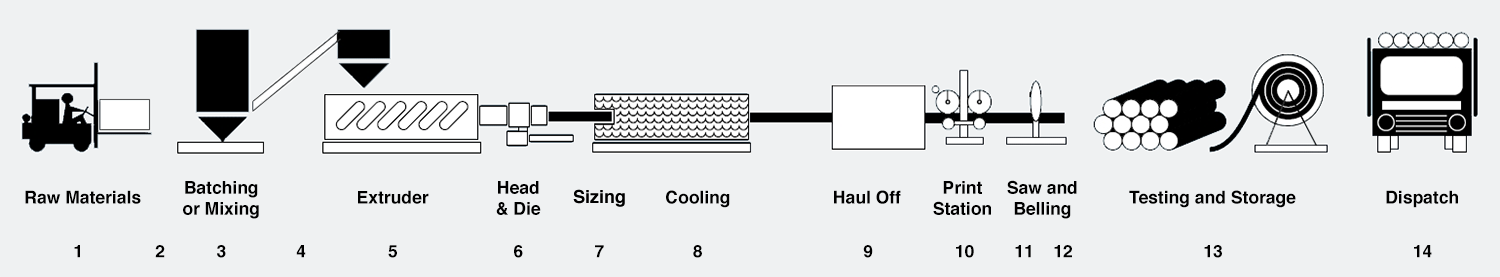

N'ụzọ bụ isi, ngwaahịa PVC sitere na ntụ ntụ PVC raw site na usoro okpomọkụ na nrụgide.Isi usoro abụọ a na-eji emeputa bụ extrusion maka ọkpọkọ na ịkpụzi injection maka ihe ndozi.

Nhazi PVC ọgbara ọhụrụ gụnyere ụzọ sayensị mepere emepe nke chọrọ njikwa ziri ezi na mgbanwe usoro.Ihe eji eme ihe na polymer bụ ntụ ntụ na-asọ asọ n'efu, nke na-achọ mgbakwunye nke stabilizers na nhazi ihe enyemaka.Nhazi na ngwakọta bụ usoro dị oke egwu nke usoro a na-edobe nkọwa siri ike maka akụrụngwa na-abata, batching na ịgwakọta.Nri maka extrusion ma ọ bụ igwe na-akpụzi nwere ike ịbụ kpọmkwem, n'ụdị "ngwakọta akọrọ", ma ọ bụ buru ụzọ hazie ya ka ọ bụrụ "mkpokọta" granular.

Extrusion

A na-atụ polymer na ihe mgbakwunye (1) nke ọma (2) wee hazie ya site na ngwakọta oke ọsọ (3) iji gwakọta akụrụngwa n'ime ngwakọta akọrọ akọrọ ekesara n'otu n'otu.A na-enweta okpomọkụ na-agwakọta ihe dị ka 120 Celsius site na okpomọkụ nke esemokwu.N'oge dị iche iche nke usoro ngwakọta, ihe mgbakwunye na-agbaze ma jiri nwayọọ nwayọọ na-ekpuchi PVC polymer granules.Mgbe ị nwetasịrị okpomọkụ achọrọ, ngwakọta ahụ na-akpaghị aka na-abanye n'ime ụlọ dị jụụ nke na-ebelata okpomọkụ ngwa ngwa ruo ihe dịka 50 ° C, si otú a na-enye ohere ka ebuga ngwakọta ahụ na nchekwa etiti (4) ebe a na-enweta ọbụna okpomọkụ na njupụta.

Obi nke usoro a, extruder (5), nwere ogbunigwe a na-achịkwa okpomọkụ, nke nwere mpaghara mpaghara nke na-atụgharị "skru" ziri ezi.Ihe nkedo extruder nke oge a bụ ngwaọrụ dị mgbagwoju anya, ejiri nlezianya mee ya na ụgbọ elu dịgasị iche iche iji chịkwaa mkpakọ na ịkwa akwa, nke emepụtara na ihe ahụ, n'oge usoro niile nke usoro ahụ.Nhazi skru na-agbanwe ejima ejima nke ndị isi niile na-emepụta ihe na-enye nhazi nke ọma.

A na-atụgharị PVC dryblend n'ime gbọmgbọm na kposara, nke na-agbanwe ngwakọta akọrọ n'ime ọnọdụ "gbazee" achọrọ, site na okpomọkụ, nrụgide na ịkwa akwa.N'oge ọ na-agafe na kposara, PVC na-agafe n'ọtụtụ mpaghara na-agbakọ, homogenise ma na-ekupụ iyi gbazee.Mpaghara ikpeazụ na-abawanye nrụgide na-agbaze agbaze site na isi wee nwụọ set (6) nke a na-eme ka nha nke ọkpọkọ chọrọ na njirimara na-asọba nke iyi gbazee.Ozugbo ọkpọkọ hapụrụ extrusion nwụrụ, a na-atụle ya site n'ịgafe n'aka uwe nke ziri ezi nke nwere oghere mpụga.Nke a zuru ezu iji mee ka oyi akwa PVC dị n'èzí sie ike ma jide dayameta ọkpọkọ n'oge oyi ikpeazụ n'ime ụlọ na-edozi mmiri na-achịkwa (8).

A na-adọta ọkpọkọ site na nha na arụ ọrụ jụrụ oyi site na puller ma ọ bụ ebugharị (9) na ọsọ ọsọ mgbe niile.Njikwa ọsọ dị ezigbo mkpa mgbe a na-eji ngwá ọrụ a eme ihe n'ihi na ọsọ a na-adọta ọkpọkọ ga-emetụta mgbidi mgbidi nke ngwaahịa emechara.N'ihe gbasara mgbanaka rọba jikọtara ọkpọkọ, a na-eji nwayọọ na-apụ apụ n'oge kwesịrị ekwesị iji mee ka ọkpọkọ dị na mpaghara oghere.

Ihe nbipute in-line (10) na-akara ọkpọkọ n'oge oge, yana njirimara dịka nha, klaasị, ụdị, ụbọchị, Nọmba ọkọlọtọ, na nọmba extruder.Igwe nbipu akpaaka (11) na-egbutu ọkpọkọ n'ogologo achọrọ.

Igwe mgbịrịgba na-etolite oghere na nsọtụ ogologo ọkpọkọ ọ bụla (12).Enwere ụdị oghere abụọ n'ozuzu.Maka ọkpọkọ ejikọtara roba na mgbanaka, a na-eji mandrel nwere ike ịdaba, ebe a na-eji mandrel dị larịị mee oghere ndị jikọtara ọnụ.Ọkpụkpọ mgbanaka rọba chọrọ chamfer na spigot, nke a na-egbu ma ọ bụ n'ọdụ ụgbọ mmiri ma ọ bụ ngalaba mgbịrịgba.

A na-echekwa ngwaahịa emechara n'ebe ejidere maka nyocha na nyocha ụlọ nyocha ikpeazụ yana nnabata ịdị mma (13).A na-anwale ma nyochaa mmepụta niile dịka ọkọlọtọ Australia kwesịrị ekwesị na/ma ọ bụ nkọwapụta nke onye zụrụ ya.

Mgbe nyocha na nnabata, a na-echekwa ọkpọkọ ahụ ka ọ chere nzipu ikpeazụ (14).

Maka ọkpọkọ PVC (PVC-O) na-adabere na ya, usoro extrusion na-esote usoro mgbasawanye ọzọ nke na-ewere ọnọdụ n'okpuru ọnọdụ akọwapụtara nke ọma ma jiri nlezianya na-achịkwa nke okpomọkụ na nrụgide.Ọ bụ n'oge mgbasawanye ka nhazi ihe omimi, nke na-enye ike dị elu nke ụdị PVC-O, na-eme.

Ịkpụzi injection

A na-emepụta ihe ndị dị na PVC site na ịkpụzi injection dị elu.N'adịghị ka extrusion na-aga n'ihu, ịkpụzi bụ usoro cyclic na-emegharị ugboro ugboro, ebe a na-ebuga "ogbugba" nke ihe na-akpụzi na okirikiri ọ bụla.

Ihe PVC, ma n'ụdị ntụ ntụ ngwakọta akọrọ ma ọ bụ ụdị ngwakọta granular, na-enye ike ndọda site na hopper dị n'elu ngalaba ịgba ntụtụ, n'ime ụlọ gbọmgbọm ihe ịghasa na-atụgharị.

A na-ebuba gbọmgbọm ahụ na ego plastik achọrọ site na ịghasa na-atụgharị ma na-ebuga ihe ahụ n'ihu gbọmgbọm ahụ.Etinyere ọnọdụ nke ịghasa ka ọ bụrụ “nha mgbụgba” agbagoro agbagoro.N'oge a na-eme ihe, nrụgide na okpomọkụ "plasticise" ihe onwunwe, nke ugbu a na ya gbazee ala, na-echere injection n'ime ebu.

Ihe ndị a niile na-ewere ọnọdụ n'oge okirikiri jụrụ oyi nke ogbugba gara aga.Mgbe oge atọrọ, ebu ahụ ga-emeghe, a ga-ewepụkwa ihe dabara adaba n'ime ya.

Akpụkpọ ahụ na-emechi wee tinye plastik gbazere n'ihu gbọmgbọm ahụ n'okpuru nrụgide dị elu site na ịghasa na-eme ugbu a dị ka onye na-agbapụta.Plastic na-abanye n'akpụkpọ ahụ iji mepụta ihe na-esote.

Mgbe ịgba ọgwụ mgbochi ahụ gasịrị, ịchaji na-amalite mgbe ihe a kpụrụ akpụ na-aga n'ihu n'usoro jụrụ oyi.

Oge nzipu: Jun-23-2022